Manufacturing Management

Manufacturers are facing a disastrous situation today, with growing global competition and constantly increasing demand from customers for newer and better products, resulting in product proliferation. This requires continuous support for more and more products with changing configurations than ever before while the product lifespan is contracting dramatically. On top of all this, at the factory floor, which is the center of supply chain customer demands, production resources and supply shipments meet-and sometimes clash, the orders change, supply deliveries are missed and machines break, making matters even worse. Manufacturing under these constraints, in the present global economic meltdown, can result in a business catastrophe without supporting tools and techniques.

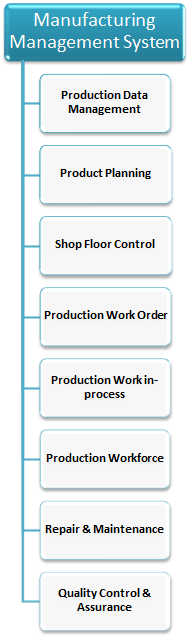

To face the above challenges, manufacturers today need enhanced vision, improved techniques and dynamic flexibility. HoneycombERP® Manufacturing Management provides you the required strength. The modules of the Manufacturing Suite are given on the side bar and the business benefits include:

• Improved product management

• Reduced time-to-market for new product

• Improved manufacturing with lower manufacturing costs

• Reduced product and engineering changes costs

• Improved speed and accuracy of product estimates

• Ensures product quality with a centralized product information repository

• Increased visibility and operational control

• Increased resource utilization and lowered manufacturing costs

• Reduced production bottlenecks and improve equipment idle time

• Improved product on-time delivery performance

To remain competitive, you must be able to constantly introduce and improve products, while continually reducing cost. You also need to synchronize your engineering, manufacturing, quality

and materials teams-as well as your suppliers — with constantly changing product information.

HoneycombERP® Product & Manufacturing Management helps you define and manage your products and allows you to respond to your customers promptly, while minimizing the disruption at every process. HoneycombERP® Product & Manufacturing Management supports designing, engineering, manufacturing, post-sale service and even financial accounting processes to give you total control of the entire product lifecycle.

HoneycombERP® Product & Manufacturing Management, the core of Honeycomb® provides you with the control you need over product costs, estimates, and configurations so you can better deliver products on time and within budget. You can manage and track all product-related information using multiple Bills-of-Materials and routings — including revisions and alternates — as well as support progressive improvements.

HoneycombERP® Product & Manufacturing Management provides manufacturers with a centralized repository for all product-related data to help speed new product development, compress time-to-market, reduce development costs and manage large product portfolios. Our solution also includes powerful estimating capabilities to help you quickly prepare accurate sales quotes and bids for your manufactured products.

HoneycombERP® Product & Manufacturing Management gives you the control you need over all aspects of production planning and materials management so you can focus each day on increasing profits.

Our flexible solution supports the entire spectrum of manufacturing styles-from High Volume to Engineer-to-Order-and coordinates orders, equipment, facilities, inventory, and work-in-progress to minimize costs and maximize on-time delivery. The solution includes powerful shop floor functionality to track and manage each step of the manufacturing process.

HoneycombERP® Product & Manufacturing Management translates your supply chain plan into an achievable production plan that balances the needs of sales, manufacturing, finance, and your customers. HoneycombERP® Product & Manufacturing Management also includes both finite and infinite capacity planning capabilities that help you develop realistic plans.

HoneycombERP® Product & Manufacturing Management helps you succeed by providing more visibility, flexibility, and control to make you highly responsive, integrated, and lean. Our manufacturing solution provides with true insights into your needs. You can deploy our solution tactically to manage and run just a division or strategically the entire factory and related business structures, so you can manage your enterprise around the clock, and around the world with a single, integrated solution.

Product Data Management

- Product Workflow

- Product and Process Families

- Product Recipes

- Process Definition with Sequence

- Multiple UOMs with Conversions

- Product Bill Of Materials

- Product Packing’s

- Product Catalogs

Product Planning

- Powerful Scheduling Tools

- Planner’s Workbench

- Use Product Recipes

- Work Center Capacity Planning

- Work Order Planning

- Bill of Materials Planning

- Multiple Planning Cycles

- Financial Measurement

Shop Floor Control

- Hierarchical Work Centre Definitions

- Machines & Workforce Allocation

- Work Center Capacity Management

- Work Center Scheduling

- Create Item-Specific Routings

- Work Center Document Management

- Work Center Flexible Reporting

Production Work Order

- Flexible Work Orders Structure

- Material Commitments to Work Order

- Tracks Material & Labor Costs

- Establishes Consumption Timetable

- Multilevel Back Flushing

- Bills of Materials & Routings

- Multiple Costing Methods

- Work-In-Process Visibility

Production Work-in-Process

- Automatic Process Assignment

- Runtime Option for Change In Product Route

- Sub/Merge Lot, Rework &, Change Control

- Process Travel Card (PTC)

- Job Card with Lot History

- Activate / Deactivate Lot & Batch Controls

- External & Internal Vendor’s Processing

- Financial Visibility of Work-In-Process

Production Workforce

- Workload Forecasting

- Workforce Requirement Planning

- Workforce Scheduling Process

- Job Association with Workforce

- Target Association with Workforce

- Management of Work Timings

- Performance Monitoring & Analysis

- Employee Targets & Evaluations

Repair & Maintenance

- Repair Work Orders

- Fault Tracking & Assign Shops

- Internal & External Repair Job Cards

- Inspections & Repair History

- Repair Work Load Control

- Material & Tools Association

- Maintenance Job History & Tracking

- R & M Work Center Performance

Quality Control & Assurance

- Inspection at Pre, Mid & Post Levels

- Process Level Check Lists

- Multiple Process Tests

- Manages Quality Sampling Procedures

- Defect Checking

- Data Ranges for Acceptance or Rejection

- Tests Parameters Verification